Stainless steel exhaust systems, like grades 304 and 409, are designed for automotive conditions with specific alloy blends. 304 offers higher corrosion resistance (18% chromium, 8% nickel) and strength, ideal for long-term durability but pricier. 409 has lower chromium (12-14%) and minimal nickel, providing a more affordable option with slightly reduced resistance to corrosion. Both contain alloying elements like molybdenum, manganese, and titanium to enhance properties like toughness and high-temperature strength. The choice between them depends on budget, application needs, and environmental factors, with 304 suitable for diverse conditions but 409 a more cost-effective basic option.

Exploring the nuances between 304 and 409 stainless steel exhaust is paramount for professionals in the automotive, maritime, and industrial sectors. This article delves into the distinct compositions of these alloys, highlighting their varying chromium and nickel content, and how these differences translate into performance characteristics. We’ll examine heat resistance, corrosion resilience, and mechanical properties, offering insights into suitable applications and cost considerations. Understanding these stainless steel grades empowers informed decisions for optimal exhaust system performance and longevity.

- Composition and Alloying Elements

- – Differing compositions of chromium, nickel, and other alloying elements

- – Impact on corrosion resistance, mechanical properties, and cost

Composition and Alloying Elements

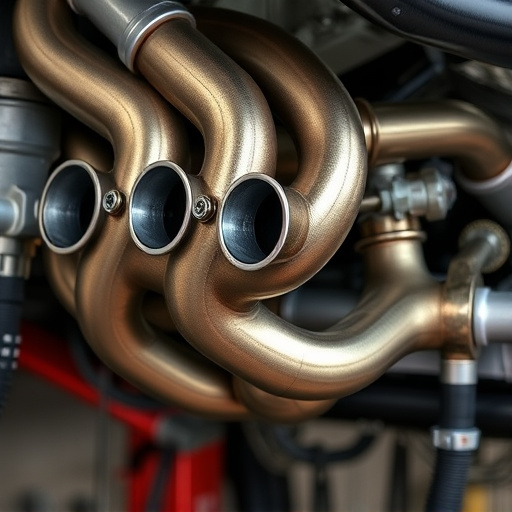

Stainless steel exhaust systems are crafted from specific alloy blends designed to withstand extreme conditions, corrosion, and high temperatures encountered in automotive applications. Two common grades, 304 and 409, offer distinct characteristics that cater to various performance needs. The composition of 304 stainless steel includes a minimum of 18% chromium and 8% nickel, providing excellent corrosion resistance and making it ideal for applications where longevity is paramount. In contrast, 409 stainless steel typically contains around 12-14% chromium and minimal nickel, resulting in lower cost but slightly reduced corrosion resistance compared to 304.

Both grades incorporate various alloying elements that further enhance their properties. For instance, molybdenum is often added to improve corrosion resistance, especially in 409 stainless steel. Manganese can also be present, contributing to improved toughness and hardening capabilities. Additionally, the inclusion of titanium in some alloys increases strength and stability at high temperatures, particularly beneficial for cat-back exhaust systems and air intake systems that experience significant thermal stress. These alloying elements play a crucial role in dictating the overall performance, durability, and service life of stainless steel exhaust components, be it a simple air filter kit or an entire system.

– Differing compositions of chromium, nickel, and other alloying elements

The primary distinction between 304 and 409 stainless steel exhaust lies in their chemical compositions. 304 stainless steel contains approximately 18% chromium and 8% nickel, offering excellent corrosion resistance and making it suitable for a variety of applications, including automotive exhaust systems. This grade is known for its strength and ability to maintain its luster over time. On the other hand, 409 stainless steel has a lower chromium content (around 12%) and minimal nickel, typically less than 2%. This composition makes it more affordable but also slightly less resistant to corrosion compared to 304.

The differing alloying elements impact the performance exhaust as well. The higher nickel content in 304 contributes to improved resistance to high-temperature oxidation, ensuring that exhaust mufflers and other components remain intact under extreme conditions. In contrast, while 409 is suitable for most automotive applications, its lower chromium and nickel contents might not be ideal for environments requiring superior corrosion protection, such as marine or heavily polluted areas.

– Impact on corrosion resistance, mechanical properties, and cost

When comparing 304 and 409 stainless steel exhaust systems, understanding their impact on corrosion resistance, mechanical properties, and cost is crucial for any automotive enthusiast looking to upgrade their vehicle’s performance parts. 304 stainless steel is renowned for its excellent corrosion resistance, making it a popular choice for high-quality exhaust systems. This grade of steel contains chromium (at least 18%) and nickel (at least 8%), which form a protective oxide layer on the metal’s surface, enhancing its durability against rust and chemicals found in car fluids.

Mechanically, 304 stainless steel offers superior strength and flexibility compared to 409. Its ability to withstand high temperatures and pressure makes it ideal for managing the intense conditions within an exhaust system. However, 304 is generally more expensive due to its higher material costs and manufacturing processes. On the other hand, 409 stainless steel boasts a lower nickel content, making it less resistant to corrosion but also significantly more affordable. While suitable for basic exhaust applications, 409 might not be as durable as 304, especially when exposed to salty environments or aggressive chemical cleaners used in some air filter kits and coilover kits.

When it comes to choosing between 304 and 409 stainless steel exhaust systems, understanding their distinct compositions is key. Both offer superior corrosion resistance, but 304’s higher nickel content enhances its durability and aesthetic appeal, making it ideal for high-performance vehicles. On the other hand, 409 steel, with its lower cost and slightly improved strength over 304, is a popular choice for stock or lightly modified cars. Ultimately, the best selection depends on individual needs, performance goals, and budget considerations for any stainless steel exhaust upgrade.